Bakery is a traditional activity and occupies an important place in food processing industry. Despite the advent of fully automatic and semi-automatic bread as well as biscuit making plants, a sizable number of people still prefer fresh bread and other products from bakery. With growing population and preference for fresh and ready-to-eat convenient food items, demand for bakery products is steadily increasing.

PRODUCTS

Applications

There are many bakery products like bread and its different variants, biscuits, cakes & pastries, cookies, puffs etc. having ready market round the year. Each product enjoys a very wide range in terms of size or weight, flavors, end-use and so on. There is a tremendous scope to introduce new varieties every year. However, this note deals only with bread and biscuits. This project can be started anywhere in the country and there is no preferred location as such. This note considers Meghalaya as the contemplated location in view of good market prospects.

Availability of technology, Quality Standards and Compliance

CFTRI, Mysore, has successfully developed the technical know-how. BIS has specified quality standards vide IS 1483:1979. Compliance under the PFA Act is mandatory.

MARKET POTENTIAL

A bakery can be set up in urban as well as rural areas. Depending upon its location, a suitable product mix can be worked out. This profile primarily considers semi-urban location from where nearby rural centers can also be catered to. In view of this consideration, the suggested products are bread and biscuits. These products are very well accepted in the market and have gained consumer acceptance.

MANUFACTURING PROCESS

Bread

Sifting of flour

Preparation of suspension

Preparation of dough by kneading all the ingredients

Fermentation of dough

Baking

Cooling and packing

The Process Flow Chart is as under:

Biscuits

Mixing of ingredients except flour in required proportion in paste form.

Preparation of dough by mixing with flour.

Placing dough in biscuit molding and cutting machine

Baking

Cooling & packing

CAPITAL INPUTS

Land and Building

It is advisable to buy a ready-made shed of around 100 sq.mtrs. which can accommodate bakery as well as retail outlet-cum-show room. The total cost could be approximately Rs. 2,50,000/- as the location has to be conveniently approachable.

Plant and Machinery

It is recommended to install bread making capacity of 72 tonnes per year considering 300 working days. Each bread would be of 400 gms and 600 breads could be made every day. Biscuit making capacity of 7.5 tonnes per year is suggested. Average weight of each packet could be 250 gms and 100 such packets may be produced each day for about 300 days every year.

To install this production capacity, following machines are required costing about Rs. 2,75,000/-.

Miscellaneous Assets

Other assets like storage bins and racks in the factory as well as retail outlet, tables, glass covered display counters, chairs etc. shall be required which would cost about Rs.1,00,000/-.

Utilities

Electricity requirement shall be 20 HP whereas per day water requirement would be 500 ltrs.

Raw Materials

The major raw material required is flour. Ideally, the unit can enter into a long term supply arrangement with an established flour mill to ensure adequate and timely supply. Other items like yeast, sugar, ghee, milk powder, salt, edible color and flavors shall be available from nearby trading centers. Since their requirement will not be substantial, supplies can be easily tied up.

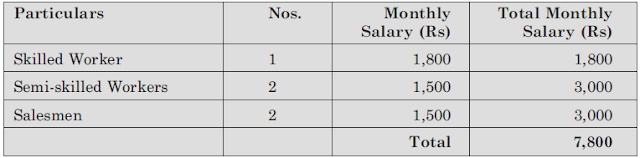

MANPOWER REQUIREMENTS

TENTATIVE IMPLEMENTATION SCHEDULE

DETAILS OF THE PROPOSED PROJECT

Building

Built up area of around 100 sq.mtrs. can comfortably accommodate bakery as well as retail outlet for which a provision of Rs. 2,50,000/- is adequate.

Plant and Machinery

The total cost is estimated to be Rs. 2.75 lacs as explained before.

Miscellaneous Assets

A provision of Rs. 1.00 lac has been made which includes retail outlet as well. Details are furnished earlier.

Preliminary & Pre-operative Expenses

Expenditure like registration charges, establishment expenses, trial run expenses etc. would be around Rs. 30,000/-.

Working Capital Requirement

It is estimated that the total working capital required in the first year at 60% capacity utilization shall be Rs. 2.04 lacs comprising of bank loan of Rs. 1.42 lacs and margin of Rs.0.62 lacs as shown below:

Cost of the Project and Means of Financing

Financial assistance in the form of grant is available from the Ministry of Food Processing Industries, Govt. of India, towards expenditure on technical civil works and plant and machinery for eligible projects subject to certain terms and conditions.

PROFITABILITY CALCULATIONS

Production Capacity and Build-up

The installed production capacity of bread making would be 72 tonnes and of biscuits 7.5 tonnes. Capacity utilization of 60% and 75% is envisaged during first two years.

Sales Revenue at 100%

Raw Materials Required at 100%

Utilities

Yearly cost of utilities at 100% activity level would be Rs.50,000/-.

Interest

It is assumed that term loan of Rs. 5.39 lacs shall be repaid in 4½ years including a moratorium period of 1 year and carry interest @ 12% per annum whereas interest on working capital is considered to be 14% per annum.

Depreciation

It is computed on WDV basis and rates assumed are 10% on building and 20% on plant and machinery and other assets.

PROJECTED PROFITABILITY

BREAK-EVEN ANALYSIS

Some machinery suppliers are

1. Industrial Equipments, Guwahati, Assam

2. Archana Machinery Stores, Guwahati, Assam

3. Delight Engg. Works, Lane No. 8, Aslatpura, Moradabad-244001

Tel No. 2498398/1687, Fax: 2494378

4. Foodmac Engg., Pvt. Ltd., 37038, Sector II, Parwanoo-173220 (HP)

Tel No. 233294/5, Fax: 233296

REFERENCES

www.eiriindia.org/automatic_bread_and_biscuit_unit_modern_bakery_plant.html

No comments:

Post a Comment